Complete Metal Forming Solutions for Precision Manufacturing

VAPTECH designs and manufactures intelligent, complete metal forming solutions that ensure reliable, efficient, and high-precision production of small, medium, and large parts across a wide range of industries — including defense, automotive, electrical, electronics, household appliances, and metal packaging.

Combining tailored engineering with a robust portfolio of standardized solutions, VAPTECH delivers cost-effective, high-performance metal pressing systems built on C-Frame and H-Frame constructions using both hydraulic and mechanical drive mechanisms. Every system is engineered for durability, productivity, and total lifecycle value.

Products and Services

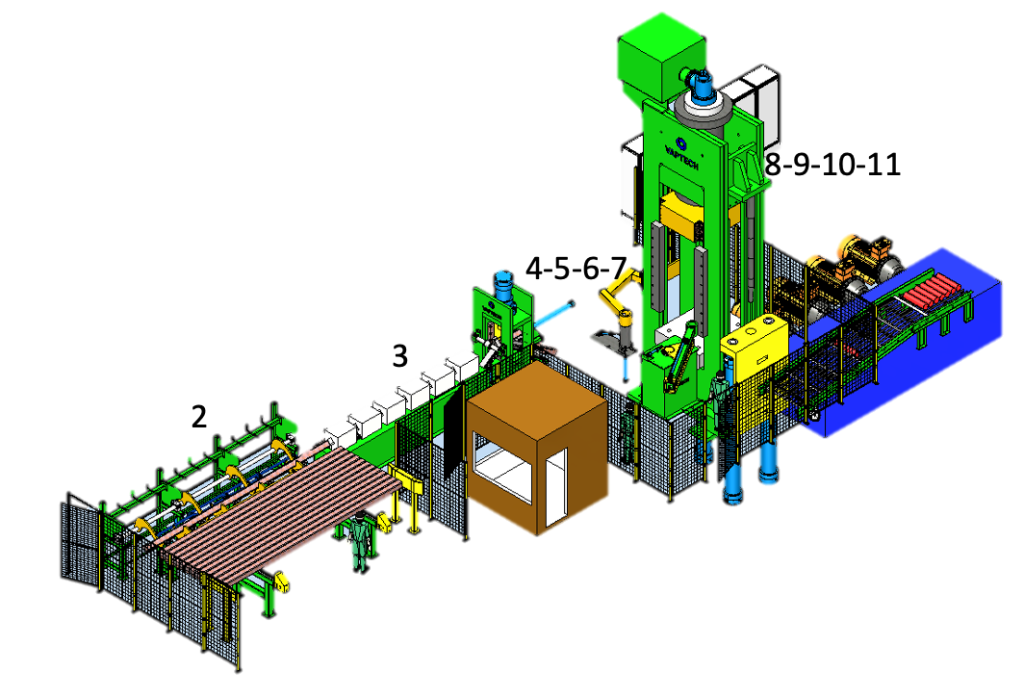

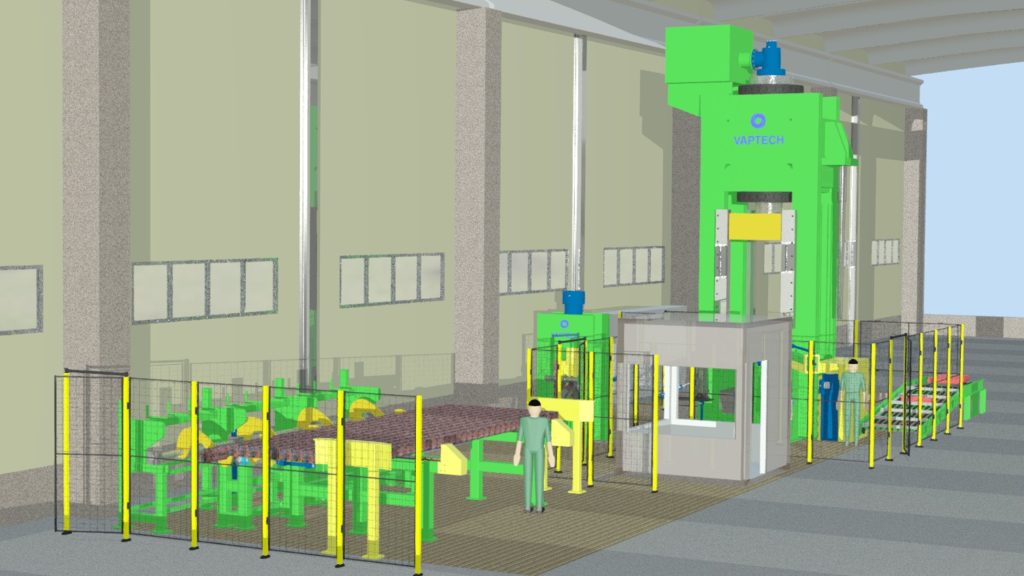

COMPLETE METAL FORMING PRODUCTION LINES

COMPLETE METAL FORMING PRODUCTION LINES

VAPTECH designs and delivers complete metal forming production lines built on hydraulic presses and mechanical presses with C-Frame and H-Frame constructions. Engineered for high-volume production, precision forming, and efficient cycle times, our press lines manufacture small, medium, and large metal…

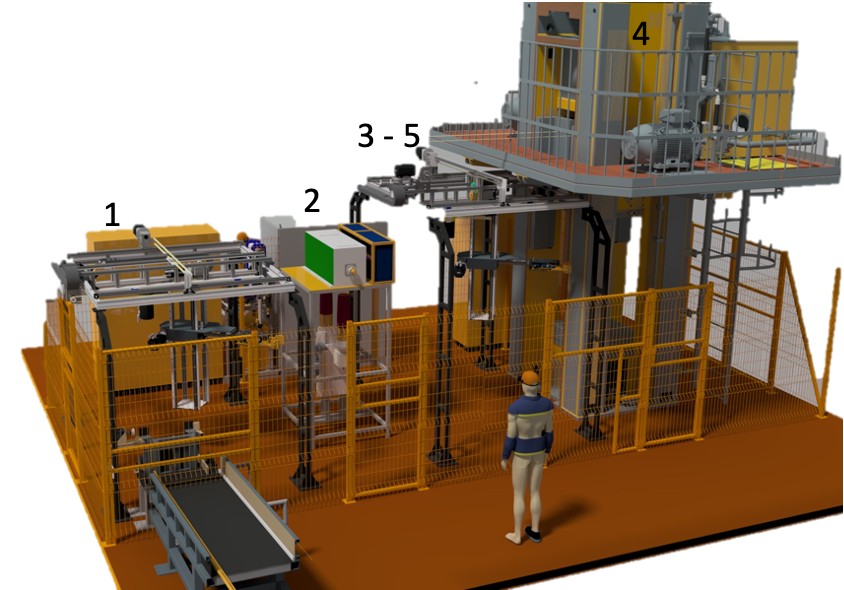

DEFENSE METAL FORMING SOLUTIONS

DEFENSE METAL FORMING SOLUTIONS

With 50+ years of expertise, VAPTECH delivers automated metal forming solutions for the defense industry, ensuring precision, reliability, and high-volume military manufacturing. Our Hydraulic and Eccentric Metal Press Lines meet the strictest production standards. Applications: Ammunition production: casings, bullets, components…

MECHANICAL H-FRAME METAL PRESSES

MECHANICAL H-FRAME METAL PRESSES

VAPTECH’s H-frame mechanical press series includes high-performance machines with nominal forces ranging from 1,600 to 8,000 kN in standard configurations — and up to 20,000 kN for fully customized solutions. Designed for versatility and demanding applications, these presses are available…

MECHANICAL C-FRAME METAL PRESSES

MECHANICAL C-FRAME METAL PRESSES

VAPTECH’s mechanical C-frame presses are engineered for cold forming operations such as stamping, punching, cutting, forging, and bending across a wide range of industrial applications. Renowned for their high production speed, precision, and stroke repeatability, these presses are a staple…

HYDRAULIC C-FRAME METAL PRESSES

HYDRAULIC C-FRAME METAL PRESSES

VAPTECH’s C-frame hydraulic presses are ideal for a wide range of forming, assembly, and disassembly operationsthat require smooth and controlled application of force. These presses are commonly used in industrial processes such as deep drawing, forming, bending, hot stamping, calibration,…

HYDRAULIC H-FRAME METAL PRESSES

HYDRAULIC H-FRAME METAL PRESSES

VAPTECH’s H-frame hydraulic presses deliver the ideal balance between high productivity and long-term reliability, with nominal force capacities ranging from 1,000 to 8,000 kN in standard models and up to 30,000 kN for custom-engineered solutions. These presses are highly adaptable…

HIGH SPEED MECHANICAL METAL PRESSES

HIGH SPEED MECHANICAL METAL PRESSES

VAPTECH’s high-speed mechanical presses deliver exceptional precision, efficiency, and performance, with force capacities ranging from 400 to 1,250 kN and operating speeds of 60 to 800 strokes per minute — ideal for high-volume production environments. Equipped with a self-balancing slide…

MODERNIZATION AND RENEWAL

MODERNIZATION AND RENEWAL

VAPTECH offers comprehensive services for the refurbishment and modernization of existing metal forming presses and production systems. Our goal is to extend equipment lifespan, improve performance, and adapt machines to new production needs. Our services include: Technical diagnostics & performance…