Complete Hydropower solutions for maximum efficiency & power generation

VAPTECH offers fully integrated hydropower solutions and services for small, medium, and large-scale projects around the world. With a strong track record in both greenfield development and rehabilitation of existing plants, we deliver complete electromechanical systems renown for their efficiency, reliability, and site-specific adaptability.

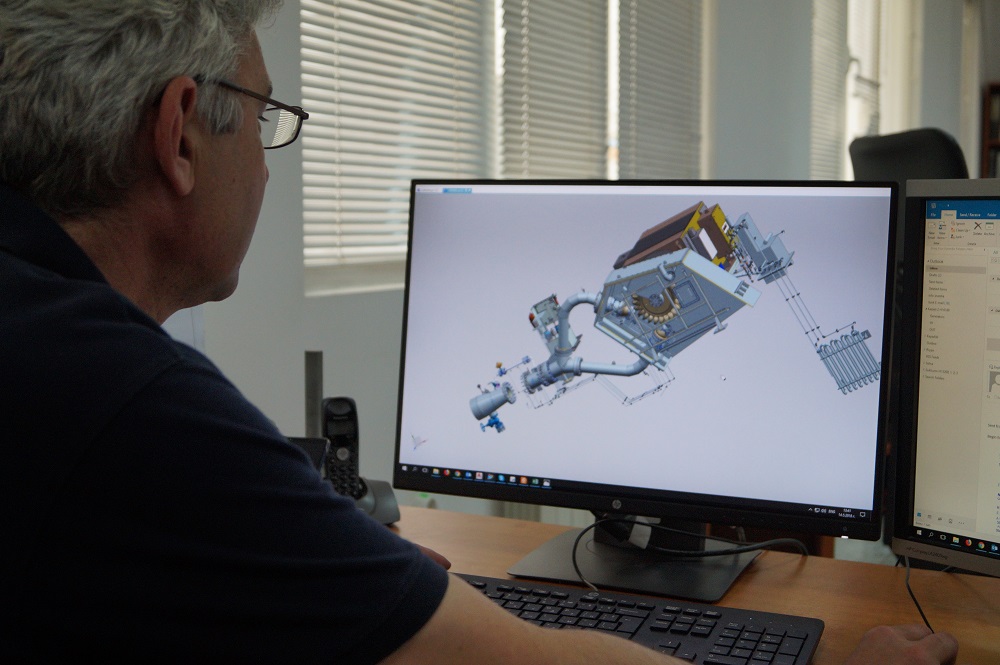

Our in-house capabilities cover the design and manufacturing of hydro turbines, inlet valves, and customized digital automation and control systems, ensuring seamless integration and performance across every component. Whether providing standalone equipment or a full turnkey solution, VAPTECH supports every stage of the project lifecycle — from engineering and production to installation, commissioning, modernization, and lifecycle service management.

Products and Services

MODERNIZATION AND RENEWAL

MODERNIZATION AND RENEWAL

Hydropower stations are engineered for longevity, often exceeding a century of reliable operation with proper maintenance and upgrades. To ensure continued performance, safety, and efficiency, modernization is essential. VAPTECH supports the renewal of existing hydropower facilities by offering: Detailed diagnostics…

Francis Hydropower solutions

Francis Hydropower solutions

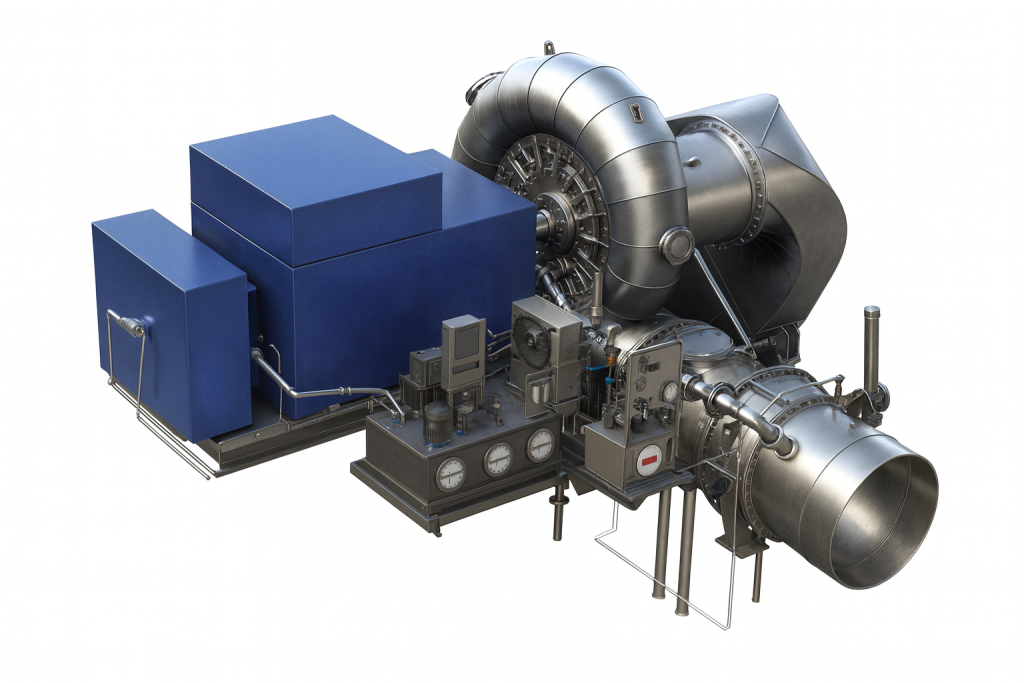

Francis turbines are ideally suited for medium-head applications with moderate flow variability. VAPTECH’s Francis turbines deliver high efficiency, low cavitation, and minimal vibration across a broad specific speed range (ns 80 to ns 300), ensuring reliable and long-term operation in…

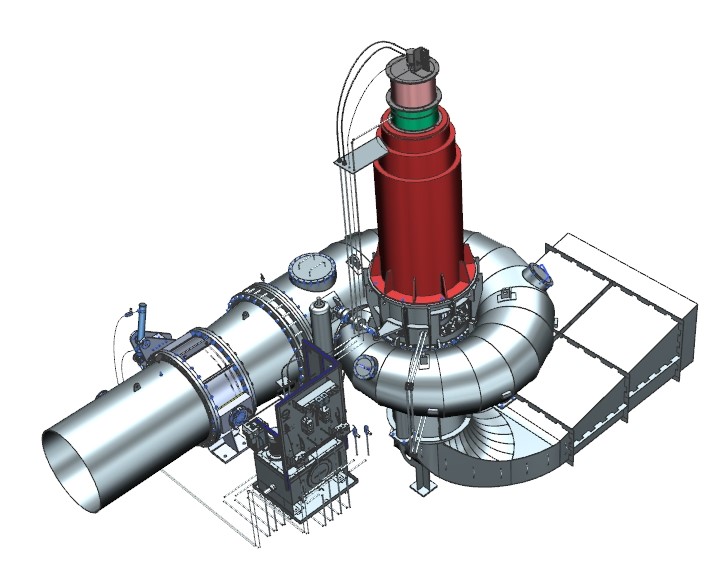

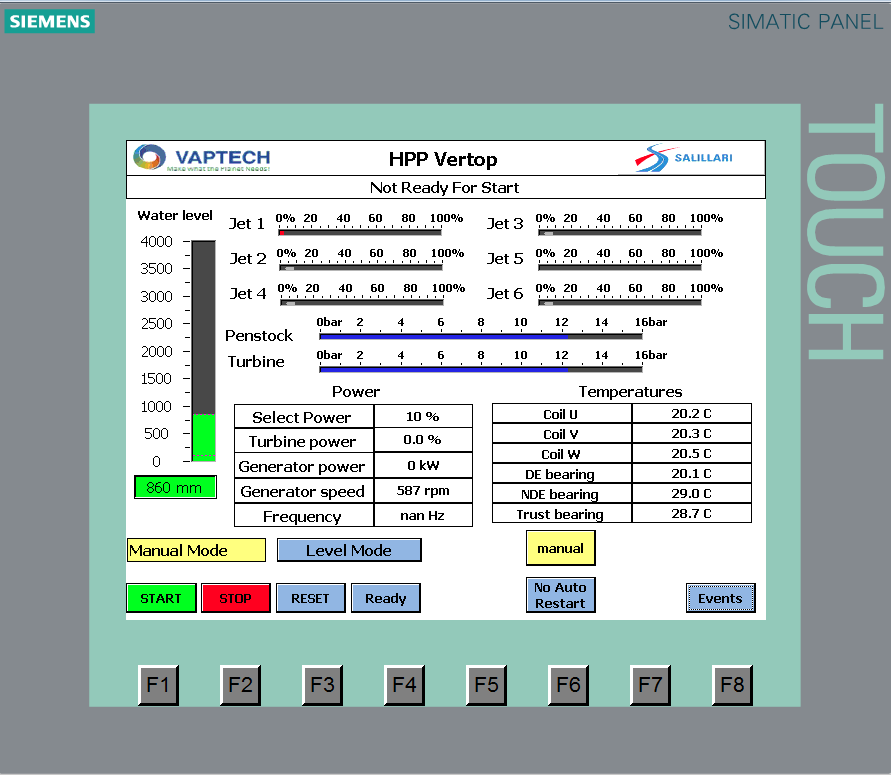

PELTON Hydropower solutions

PELTON Hydropower solutions

Pelton turbines are ideal for sites with high to medium heads and significant flow variation. VAPTECH offers customized Pelton turbine solutions with horizontal or vertical shaft configurations and 1 to 6 injectors, depending on project requirements. Our Pelton runners are…

KAPLAN Hydropower Solutions

KAPLAN Hydropower Solutions

VAPTECH’s Kaplan turbines are designed for hydropower projects with low or very low heads and significant flow variation. Available in vertical or horizontal (pit) shaft arrangements, each turbine features 3 to 6 runner blades with double regulation, ensuring optimal efficiency…

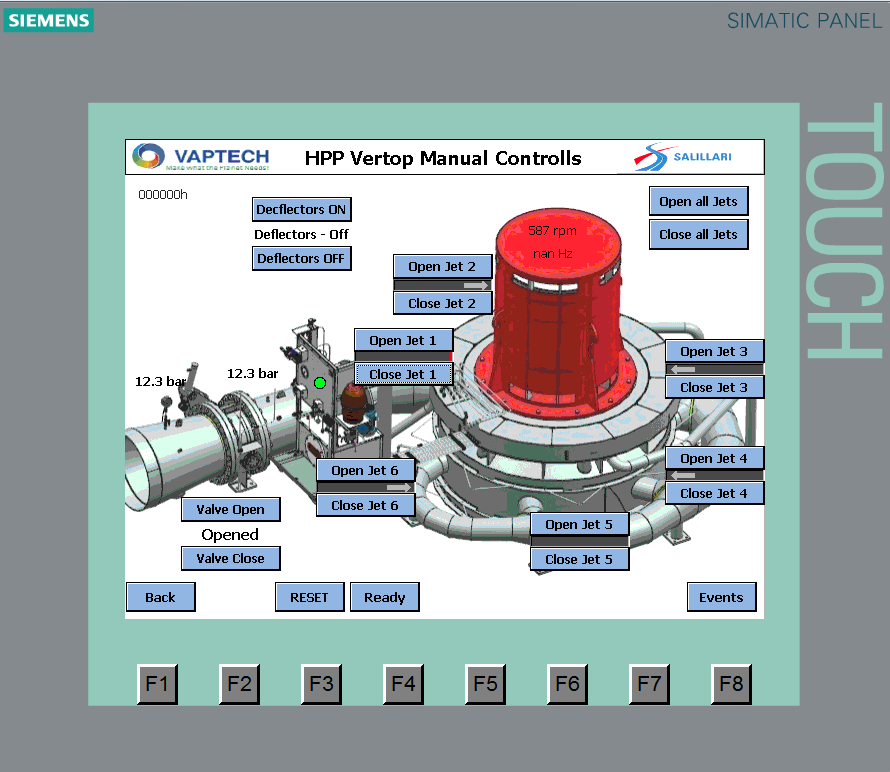

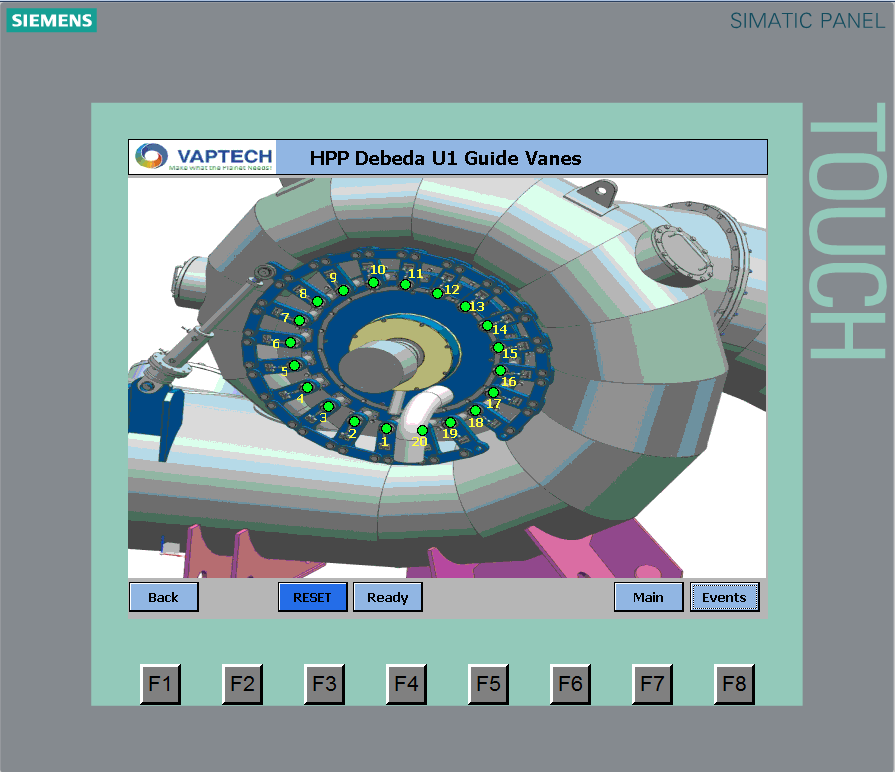

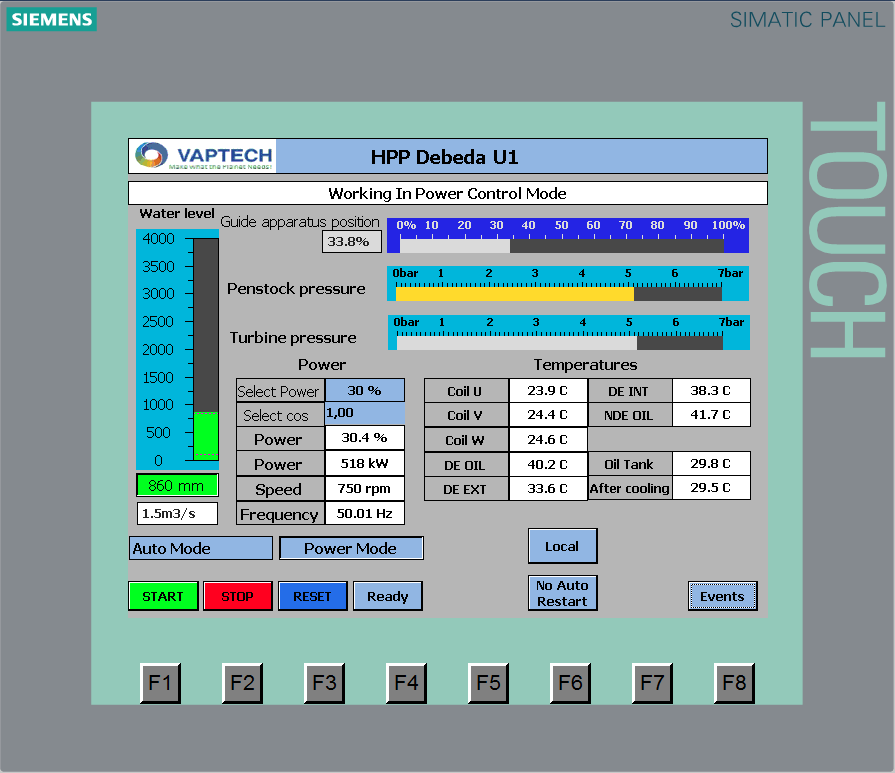

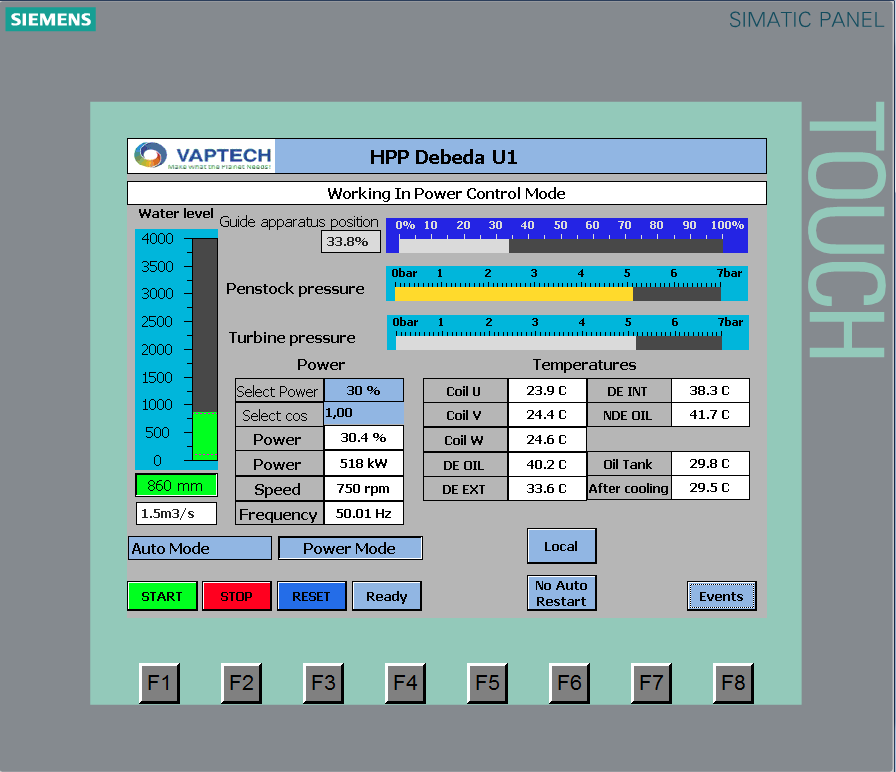

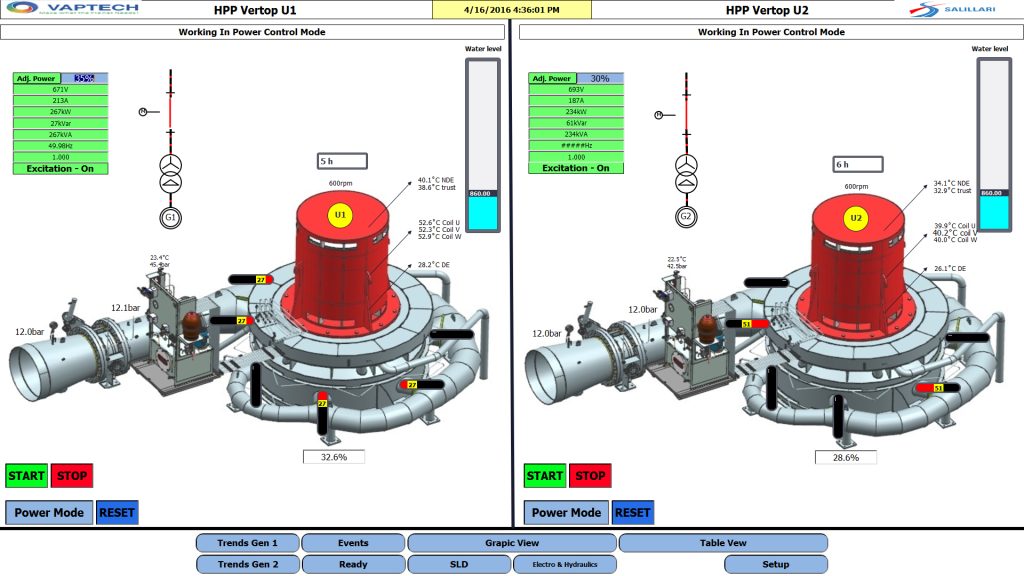

Hydropower AUTOMATION

Hydropower AUTOMATION

VAPTECH’s digital control system is engineered to ensure full automation, regulation, and seamless synchronization of all hydromechanical systems within a hydropower plant: Turbine regulation system Turbine inlet valve Bypass system Intake hydraulic steel structures Developed by VAPTECH’s in-house automation experts,…

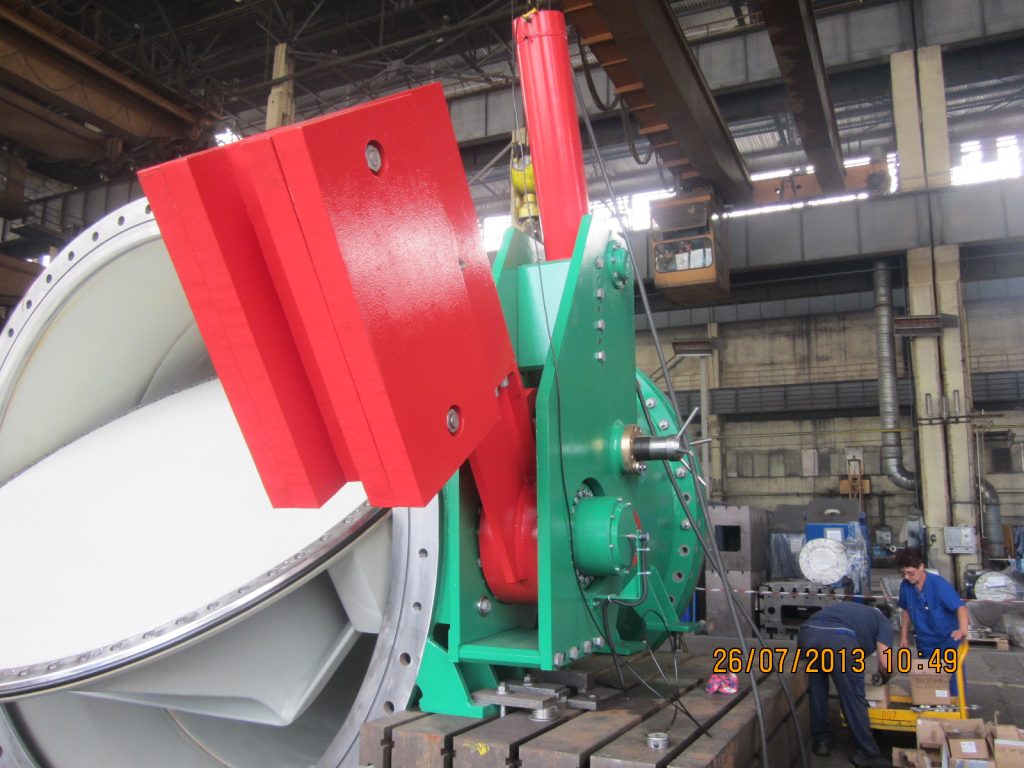

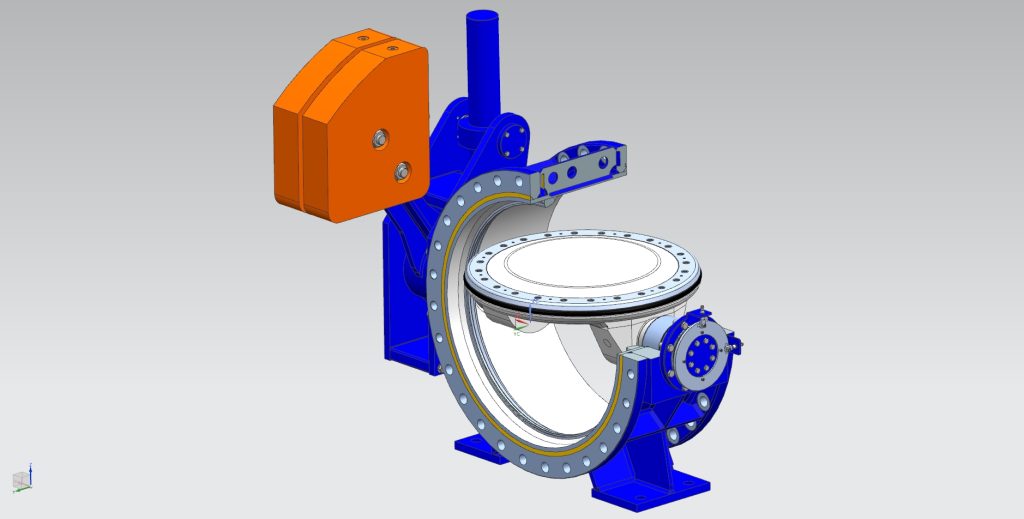

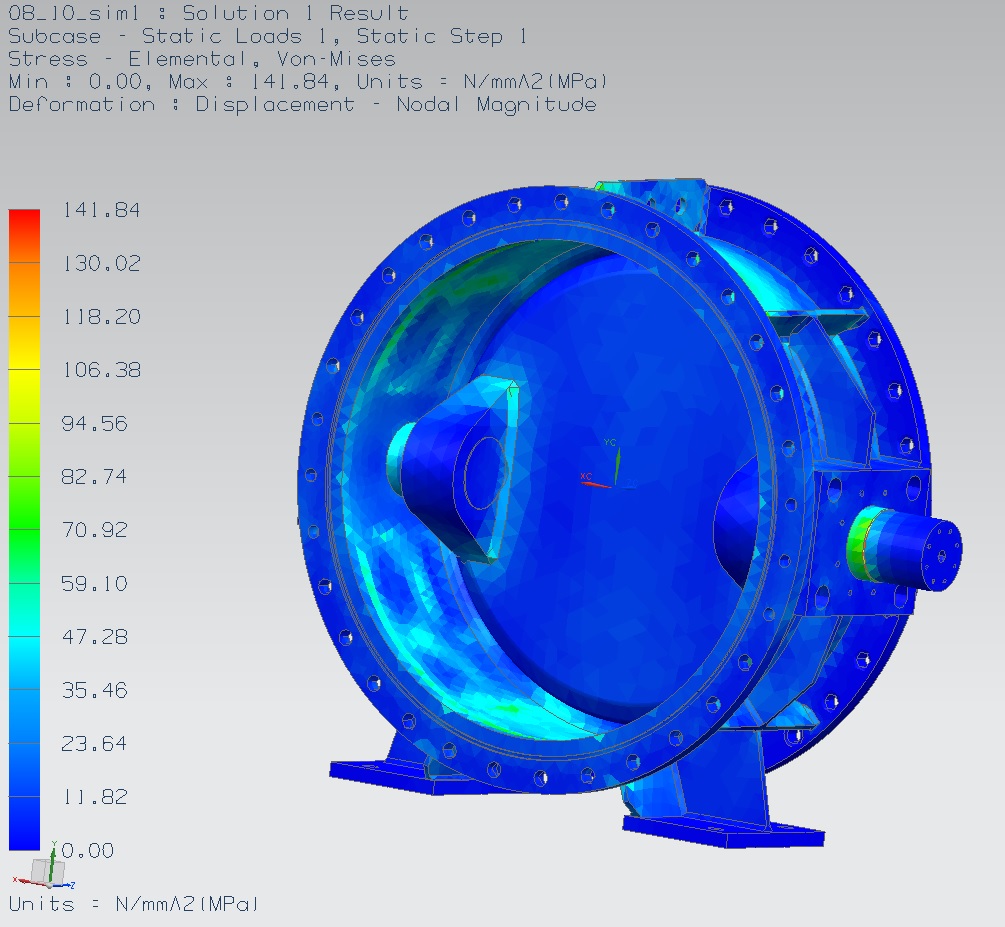

Hydropower BUTTERFLY VALVES

Hydropower BUTTERFLY VALVES

VAPTECH’s standard butterfly valves are designed for medium and low-pressure applications, covering diameters from 300 to 1400 mm and pressure ratings of 6, 10, 16, and 25 bar. Standard actuation is achieved through a hydraulic cylinder, with valve closing supported…

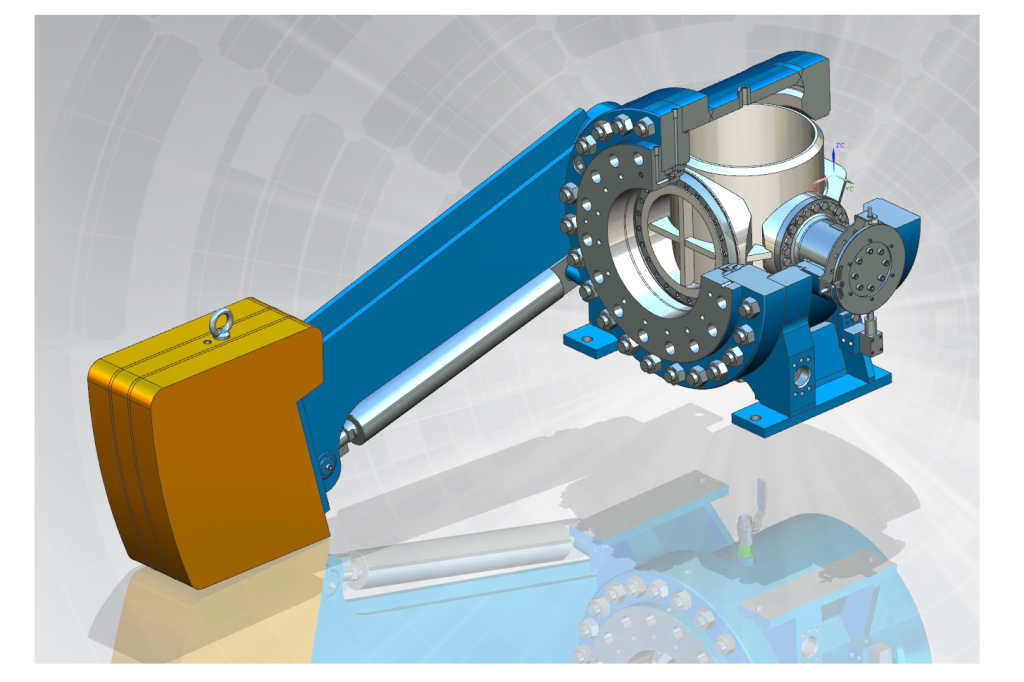

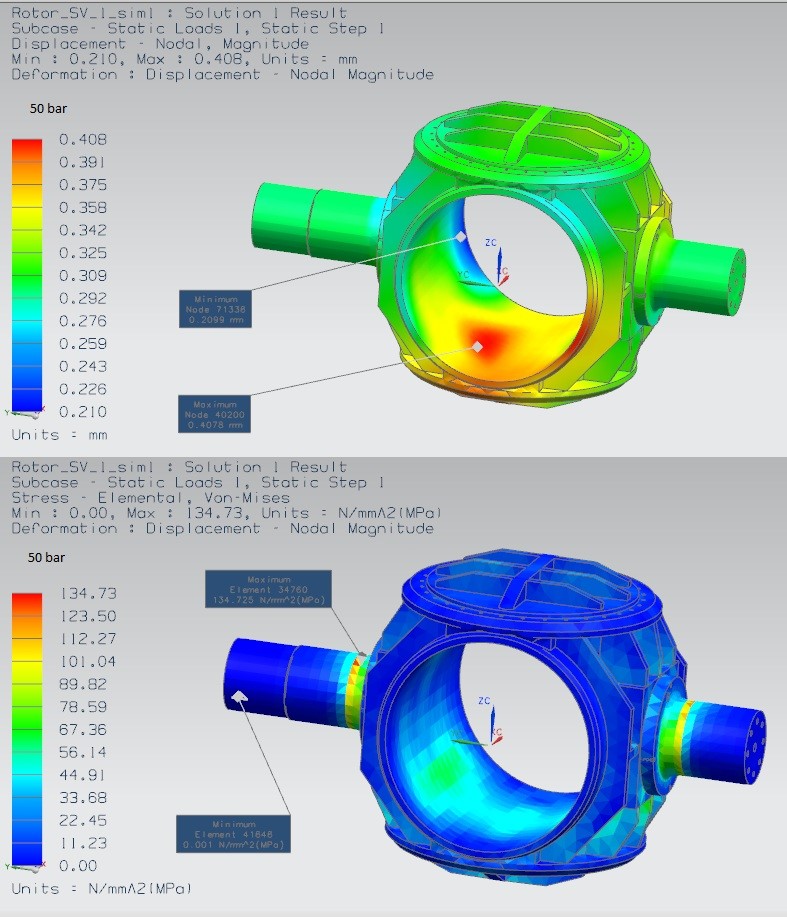

Hydropower SPHERICAL VALVES

Hydropower SPHERICAL VALVES

VAPTECH’s standard line of spherical valves is engineered for medium and low-pressure applications, covering diameters from 300 to 1000 mm and pressure ratings of 40, 63, and 100 bar. Each valve is actuated by a hydraulic cylinder, with closing ensured…